We all want to understand how digitalization impacts our work. Studies indicate that especially knowledge workers’ jobs are evolving rapidly due to new and emerging Artificial intelligence (AI) technologies. But what is the role of AI in physical elevator and escalator maintenance work? There is no room for inaccurate AI hallucinations when equipment reliability and user safety are at stake.

Heikki Mannila, a professor of computer science at Aalto University in Finland, points out that service work deals with physical objects like spare parts and hence requires a different kind of AI, compared to typical applications of large AI models.

“The AI systems in maintenance must be aware of the underlying properties and behavior of the materials: the AI should be physics-informed. Additionally, the AI assistants should be able to give tailored advice that augments the technician’s extensive experience on site. And above all, AI used in maintenance needs to be safe, robust, and trustworthy,” Mannila says.

The professor is the director of the Aalto University House of AI, which develops and applies AI methods in a multidisciplinary way. KONE collaborates closely with House of AI both institutes in applying the latest technologies with a human-centric approach, something that Mannila also values.

“It is crucial that humans are in the loop when making decisions. This is an important principle in using AI in all fields, but especially in maintenance where safety and trustworthiness are essential. It is not easy to explicitly formulate the extensive experience the technicians have for AI purposes,” Mannila adds.

Improving the daily life of technicians

KONE is harnessing the integration of AI technology to boost human potential in all areas of our business. We have, for example, optimized tendering processes and developed new AI powered tools to help serve our customers better. New technology also has a significant impact on our service technicians, who form the majority of the KONE workforce. Erik Kahlert, KONE’s senior vice president, service, explains how KONE accelerates digital to drive customer value by improving the daily life of our service technicians. service technicians.

“We use connectivity and data to fundamentally transform the way we serve our customers. We create customer value through data-driven service delivery and enhanced technician experience. Our technicians play a huge role in our business, and we invest in their growth and development,” Kahlert says.

Leading KONE’s Service business with a team of over 30,000 technicians, Kahlert has found that the profession has grown increasingly demanding. “Technicians’ work is evolving, becoming more complex and digital. For example, the range of aging elevator equipment is more diverse today than ever before. For our men and women on the field, this means balancing customer demands, local regulations, industry standards, and learning new skills.”

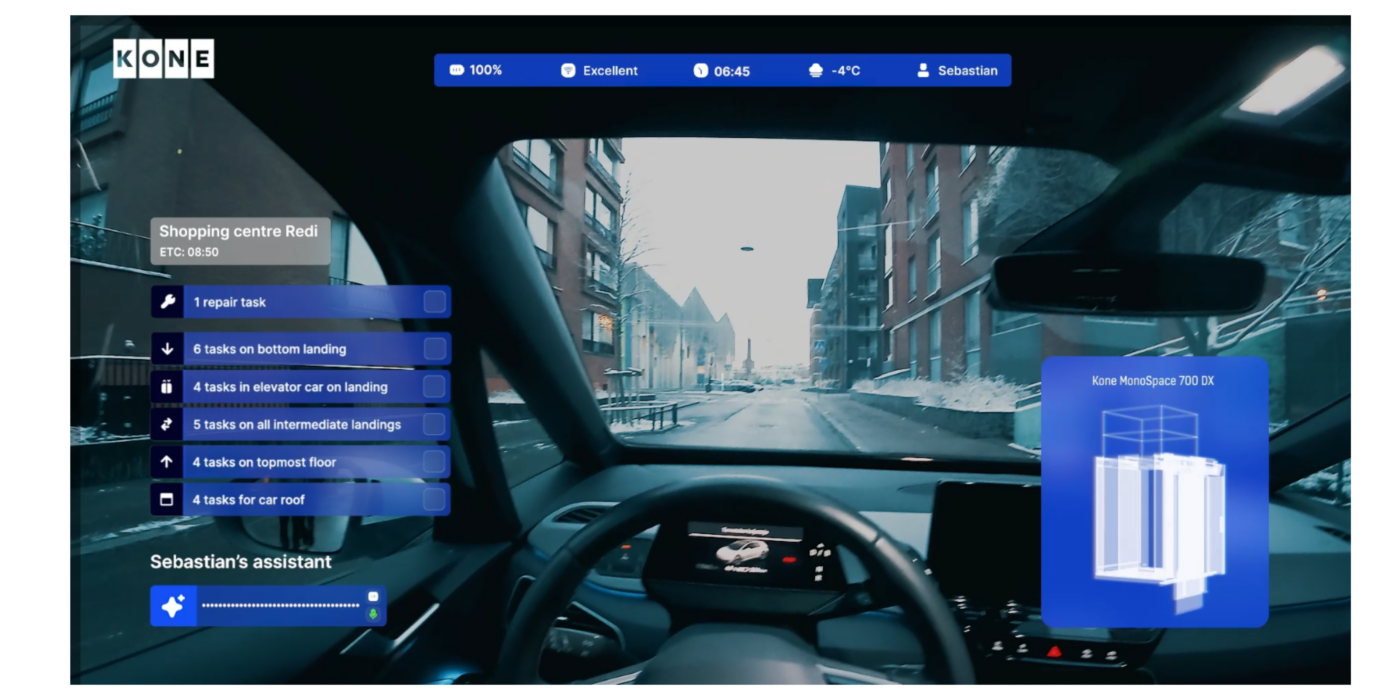

Kahlert believes that in the future, technicians need to be more digitally savvy. “We are constantly innovating new tools like AI-powered digital assistants and using Virtual Reality (VR), and these will become the norm.”

Mastering one’s craft is about lifelong learning

Reaping the benefits of AI requires developing the necessary skillset for success; every expert must commit to continuous learning.

At KONE, our goal is to recognize the unique skills across generations and encourage a culture of learning from one another. It is about harnessing technology and matching the technical competences with the people and their expertise.

“Digitalization and AI will help our technicians become even better at their work. In the future, equipment data, connectivity, and AI-assisted intelligence will form a continuous learning loop for our service technicians. These loops will enable equipment to perform self-diagnostics and self-repair actions, and free up people from mundane routine tasks so they can focus on issues requiring expertise instead,” Kahlert says.

KONE’s Senior Vice President, Research & Development, Johannes Rastas, believes that technology will play a bigger role in training in the future. The deep tacit knowledge that technicians have acquired through their years of experience, will be transformed into organizational knowledge, making it more accessible and widely usable.

“The best practices to solve issues, that used to be shared amongst team mates and passed on to apprentices, can be utilized by colleagues on the other side of the world and even by virtual AI counterparts,” Rastas envisions.

From mechanical technician jobs to state-of-the art tech roles

For Rastas, the on-site technician remains crucial for ensuring a safe and continuous people flow experience, especially in the complex building environment where elevators and escalators are part of a bigger infrastructure. However, he foresees significant changes in the role of service technicians as new technologies continue to transform the industry.

“People still think that an elevator technician works in challenging and hazardous conditions, adding oil to the equipment in poorly lit machine rooms. While that may be true to some extent, the service technician of tomorrow might work remotely on a digital twin with their laptop, wearing Augmented Reality (AR) glasses, guiding a robot in the shaft to replace a 3D-printed spare part delivered by a drone. We are currently piloting these innovations, and they will become a reality for people in the elevator and escalator service within the next ten years, mark my words,” Rastas states.

Simulating future cities with digital twins

The concept of a digital twin gets Rastas excited, and he sees huge potential in converging a digital twin with its real-world counterpart. Having a virtual representation of a physical object, system, or process like a metro station can be used for simulation, monitoring, or testing – and to an increasing extent, remote maintenance. Digital twin technology will also enable us to introduce service solutions tailored to specific customer needs.

“Digital twins will revolutionize the way service technicians work, transforming it into a ‘Matrix’-like experience. At KONE, we’re already implementing these innovations today – it is not science fiction. Digitalization is here to stay, and it is up to us how we support and embrace the human-AI collaboration,” Rastas says.

Also Kahlert emphasizes that while digital tools and technologies are transforming the industry, human craftsmanship will remain essential in delivering quality and value.

“For me, the technician – on site or remotely – is still the key expert with actual problem-solving skills. Our people are dedicated, and they take great pride in their craft, servicing the elevator or escalator well, and doing it safely. Many of our customers also view the service technician as their trusted partner onsite.”

Take a look at the inspirational video below, showing how the day of a service technician could look like in 2035.