Queues for elevators and hoists on site can be a major hold-up to the smooth flow of people and materials. But KONE SiteFlow helped shipbuilder Meyer optimize on-site logistics during the construction of the world’s largest cruise ship, Icon of the Seas.

Getting the most out of construction-time elevators is one of the keys to running a construction project smoothly and without costly delays. “With KONE SiteFlow, we were able to see the real-time data for unused elevator capacity, which allowed our workers to make informed decisions about the best routes on-site,” says Samuli Elsilä, head of Group, Logistics at Meyer Turku.

As well as giving Meyer valuable insight into previously unseen bottlenecks through a convenient app, SiteFlow also enabled direct control over elevators and on-site equipment, allowing for real-time optimization of people and material flow.

“We see also a lot of potential to use the solution in future projects to provide insights into the people and material flow on site to thousands of our employees,” Elsilä adds.

Unlocking more elevator capacity

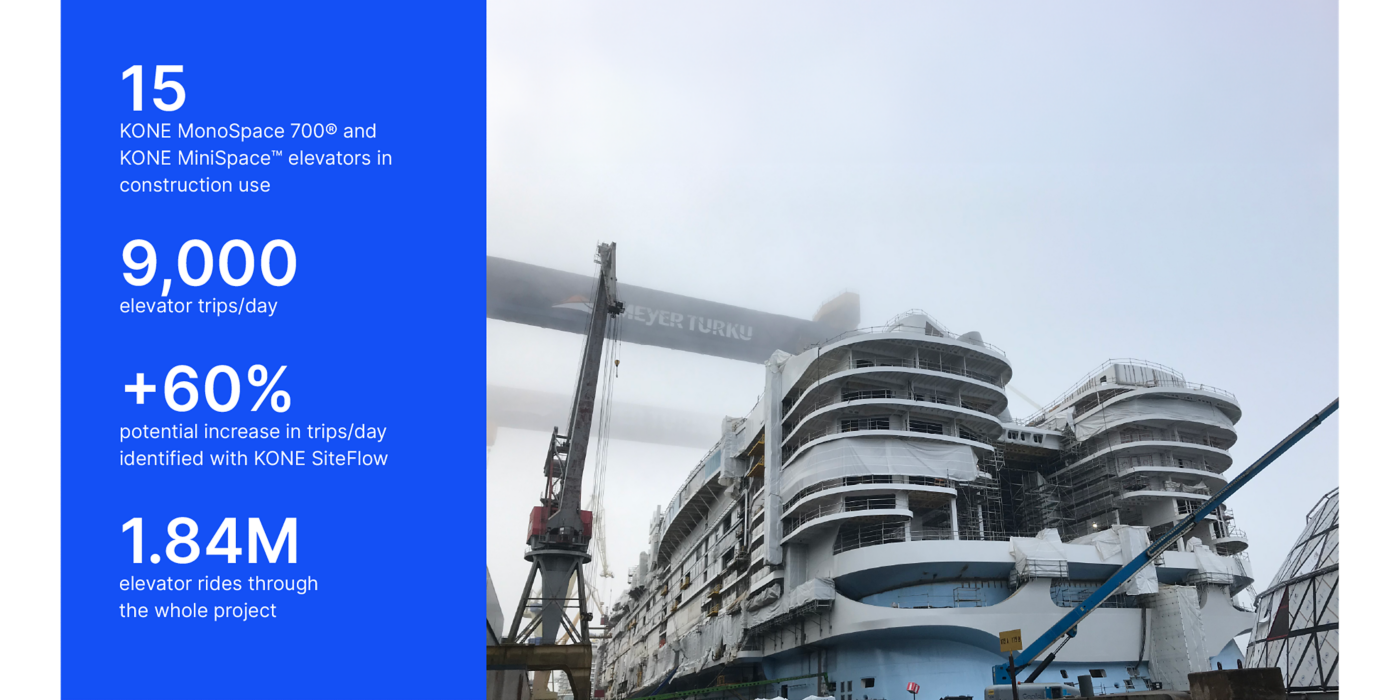

During the project, Meyer workers averaged around 9,000 rides per day during working hours. KONE SiteFlow, however, identified ways to boost the number of daily elevator trips to over 15,000 – an increase of over 60%.

The SiteFlow team installed RFID readers in the elevators and entrance gates to measure traffic flow anonymously. This gave real-time data on elevator usage rates and key logistics routes, meaning it was possible to guide people and materials to desired elevators so that they run more evenly, maximizing capacity.

Over the course of the build, the workers ended up making a staggering 1.8 million elevator trips. That’s the equivalent of 15 million floors up and down stairs.

KONE SiteFlow in a nutshell:

- Provides data and insights to optimize the productivity of construction sites

- A digital platform with an app to control construction-time elevators, e.g. restrict access to specific floors or find assets on site

- Provides real-time data and analytics for people and materials flow on-site

- RFID readers installed in the elevators and entrance gates measure traffic flow in selected locations

- Data security as a built-in feature, with full GDPR compliance

- Dashboard brings visibility to unused elevator capacity

Clearing bottlenecks

The Meyer logistics team found out that one specific elevator group faced very high traffic. The pressure on these elevators was increased even further when one of the cars was removed to complete further construction work in the shaft, significantly reducing available capacity. But people continued queuing up for these elevators as this route was familiar to them. High traffic and constant stops on every floor slowed down crucial flow to the most important decks.

To solve this, Meyer decided to use SiteFlow Floor Locks to dedicate the rest of the elevators in the group for the most important floors, and close others. This action had an immediate impact on people flow – unnecessary stops with short elevator trips ended, key floors were served faster, and most importantly, people adjusted their routes to use the elevator groups that had more available capacity.

Empowering workers to avoid delays

Project managers saw the benefits of using KONE SiteFlow, but the key to better people flow are the people working on the construction site. When constructing a vessel, the decks and access routes to workstations undergo constant changes throughout the entire project. That's why it's crucial for workers to have information on the most efficient route to use at any given time, ensuring convenient and swift access to their workstations with minimal stairway navigation.

Meyer and KONE will continue collaboration in future projects using KONE SiteFlow to provide real-time insights into the status of elevators to thousands of workers, empowering workers to make informed decisions about routes and understand their impact on overall project completion. This visibility allows workers, subcontractors, and the entire Meyer shipyard to operate more efficiently for a streamlined and more productive construction process.